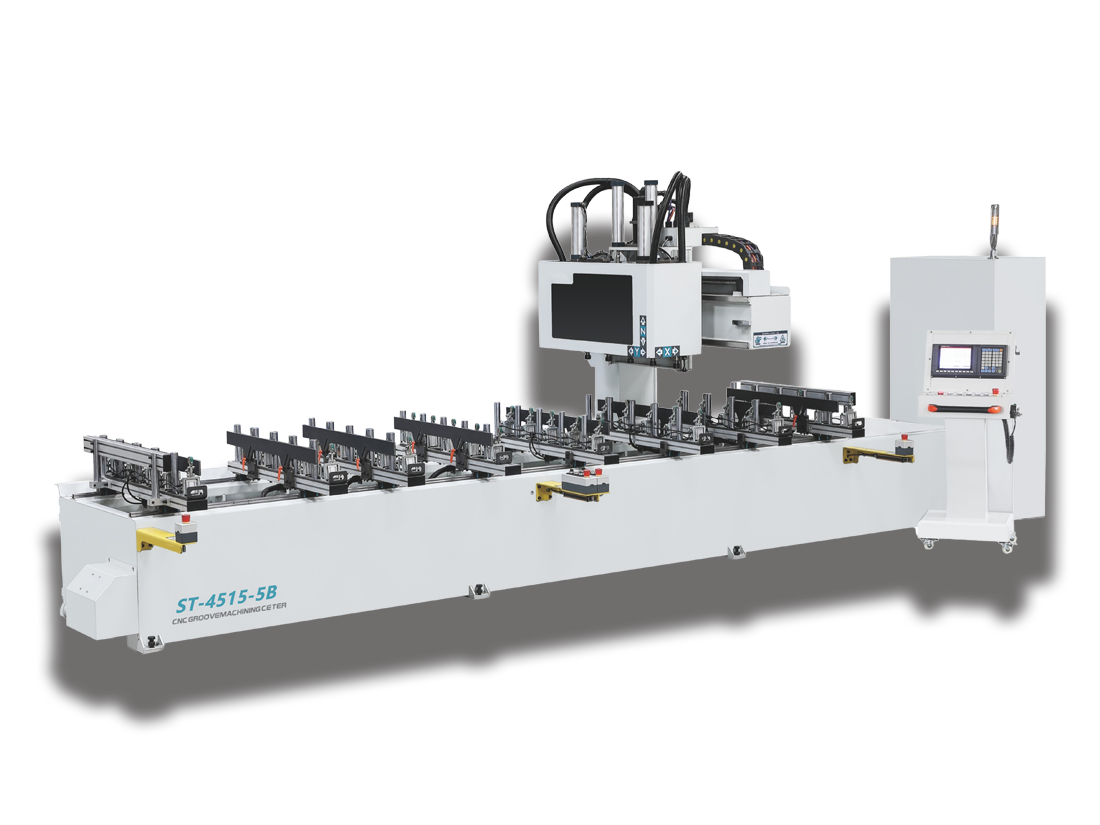

ST-4515-5B Double-Row 10-Axis CNC Slotting Machining Center

Dual-spindle high-efficiency milling / Combined hole and slot machining / CNC human-machine interface

Utilizes a double-row, ten-spindle multi-station design for simultaneous machining, significantly improving production efficiency. One set of workpieces can be loaded/unloaded while the other set is being processed.

1.Advanced CNC system for easy setup and operation; it is simple to learn, allowing general operators to be proficient within 2-3 hours.

2.No programming required; the machining program is automatically generated by capturing points from the tool holder, ensuring precise workpiece positioning.

3.High machining efficiency; continuous, non-stop cyclic processing is achieved through multi-spindle, multi-station operation across left and right working positions.

4.Wide applicability: Suitable for machining workpieces with various shapes and specifications of mortises and grooves. It offers strong practicality and demonstrates significant advantages, especially for processing complex profiles featuring multiple grooves, small-pitch groove combinations, or workpieces with grooves of varying lengths and depths on the same part.

Utilizes a double-row, ten-spindle multi-station design for simultaneous machining, significantly improving production efficiency. One set of workpieces can be loaded/unloaded while the other set is being processed.

1.Advanced CNC system for easy setup and operation; it is simple to learn, allowing general operators to be proficient within 2-3 hours.

2.No programming required; the machining program is automatically generated by capturing points from the tool holder, ensuring precise workpiece positioning.

3.High machining efficiency; continuous, non-stop cyclic processing is achieved through multi-spindle, multi-station operation across left and right working positions.

4.Wide applicability: Suitable for machining workpieces with various shapes and specifications of mortises and grooves. It offers strong practicality and demonstrates significant advantages, especially for processing complex profiles featuring multiple grooves, small-pitch groove combinations, or workpieces with grooves of varying lengths and depths on the same part.

Model | ST-4515-5B |

Processing range | 4500*150*200mm |

Saw blade | none |

Spindle power | 2.2kw*5/3.7kw*5 |

Spindle speed | 18000r/min |

Equipment power | 35kw |

Processing speed | 1-15M/min |

Return speed | 50M/min |

CNC system | Taiwan billion map |

Lubrication method | Automatic lubrication |

Dust removal method | Automatic dust collection |

Vacuum diameter | Φ150mm*1 |

Installation size | 5500*2200*2200mm |

Mechanical weight | 4T |

.png)

.png)