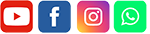

ST-2215-4A/4B CNC Mortising Machine

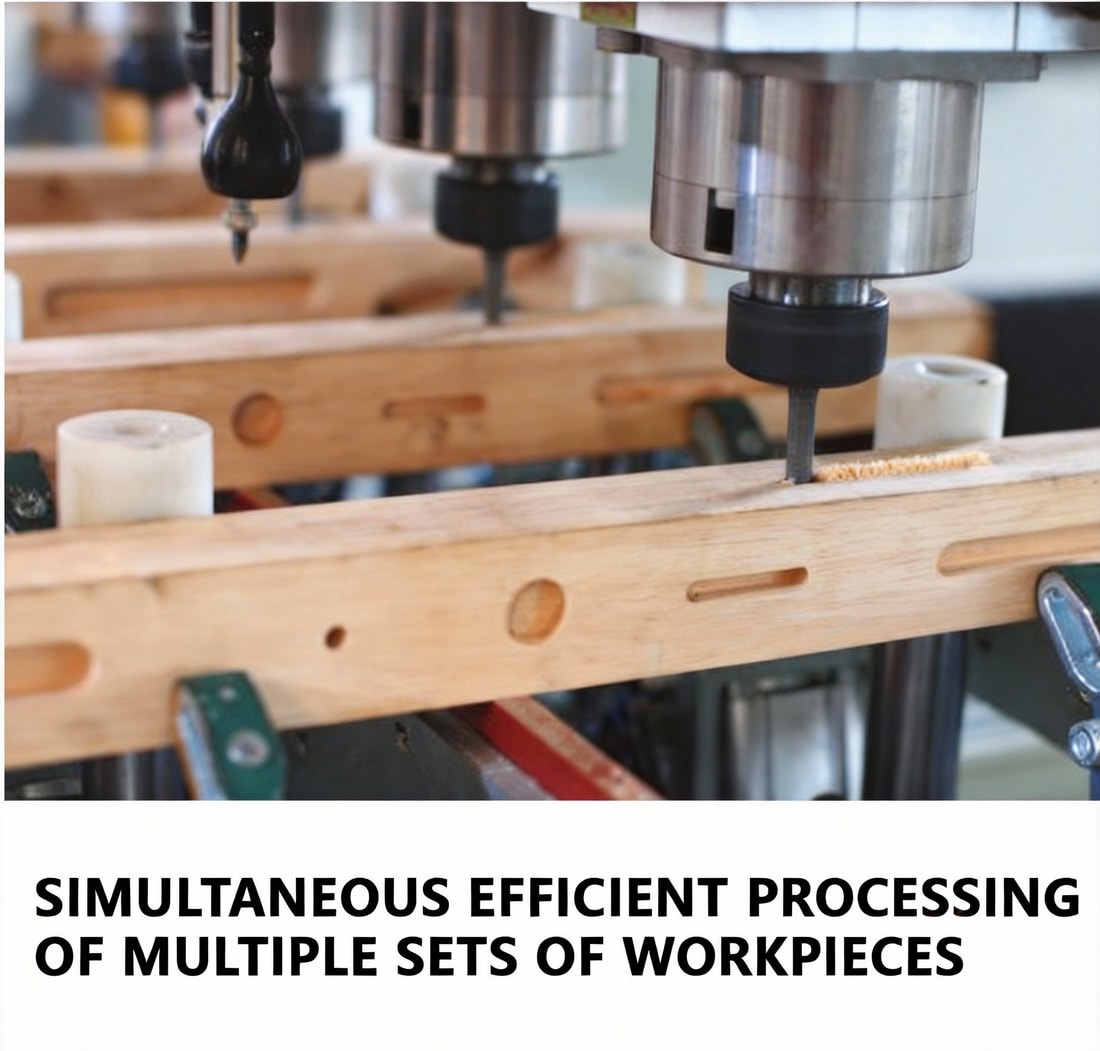

1.ST2215-4A features 4-axis, ST2215-4B features 8-axis multi-station high-speed continuous cutting. One set of workpieces is processed while others are loaded/unloaded for non-stop production, achieving over 28,000 mortises (holes) per 8-hour shift.

2.Equipped with advanced CNC system and user-friendly HMI, easy to learn. Operators only need 2-3 hours of training. Tool setting is done via a toolbar; no programming is needed, and machining programs are generated automatically with point-to-point input. Setup for a new workpiece takes only ~10 minutes.

3.Ideal for processing workpieces with various mortise (hole) shapes and specifications. Especially effective for multi-mortise workpieces, small mortise spacing, combined mortises, varying mortise lengths/depths, and complex profiled parts.

4.A classic, cost-effective model with a compact footprint.

2.Equipped with advanced CNC system and user-friendly HMI, easy to learn. Operators only need 2-3 hours of training. Tool setting is done via a toolbar; no programming is needed, and machining programs are generated automatically with point-to-point input. Setup for a new workpiece takes only ~10 minutes.

3.Ideal for processing workpieces with various mortise (hole) shapes and specifications. Especially effective for multi-mortise workpieces, small mortise spacing, combined mortises, varying mortise lengths/depths, and complex profiled parts.

4.A classic, cost-effective model with a compact footprint.

DEVICE PARAMETERS | ST-2215-4A/4B |

Processing Range | 2200×150×200mm |

Spindle Power | 2.2kW*4*4.3kW * 4 |

Spindle Speed | 18000r/min (VFD) |

Equipment Power | 28kW |

Processing Speed | 1–15m/min |

Rapid Traverse | 50m/min |

CNC System | LNC (Taiwan) |

Lubrication Method | Automatic Timed Lubrication |

Installation Size | 2700×2300×2200mm |

Machine Weight | 2.8T |

.png)

.jpg)

.jpg)

.jpg)

.png)