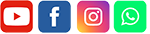

ST-1212 Double-End Machining Center

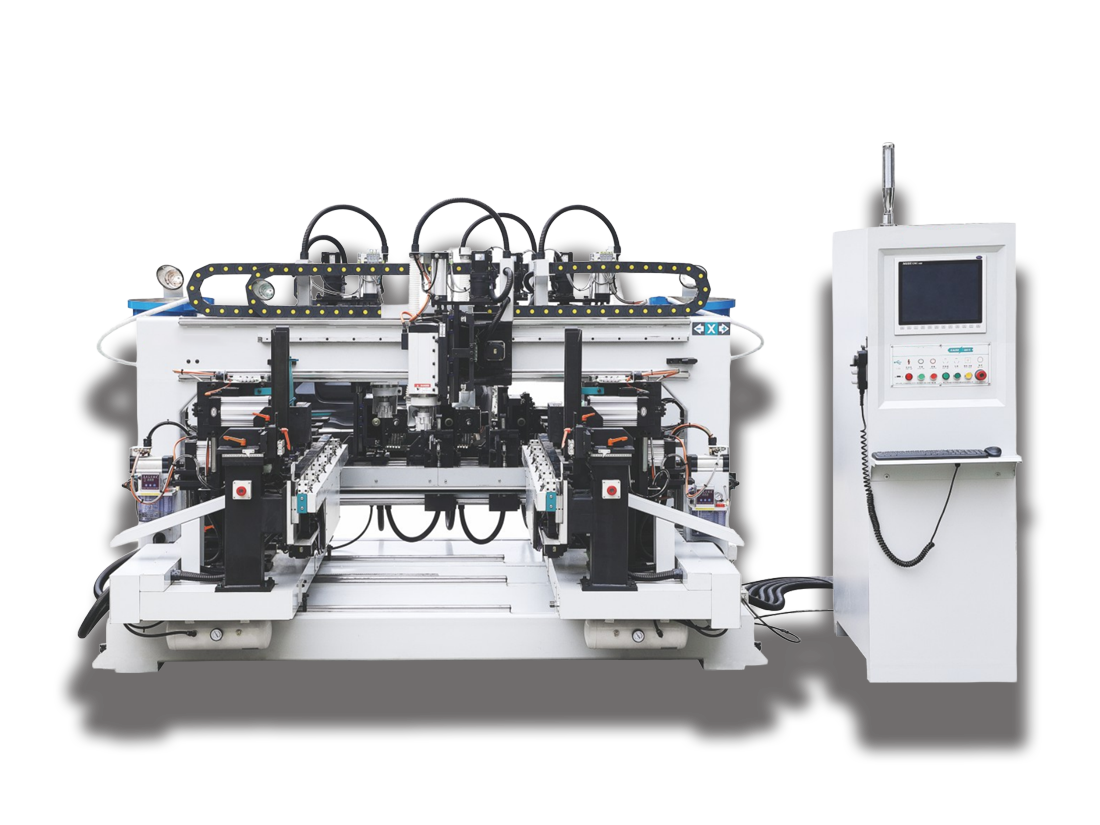

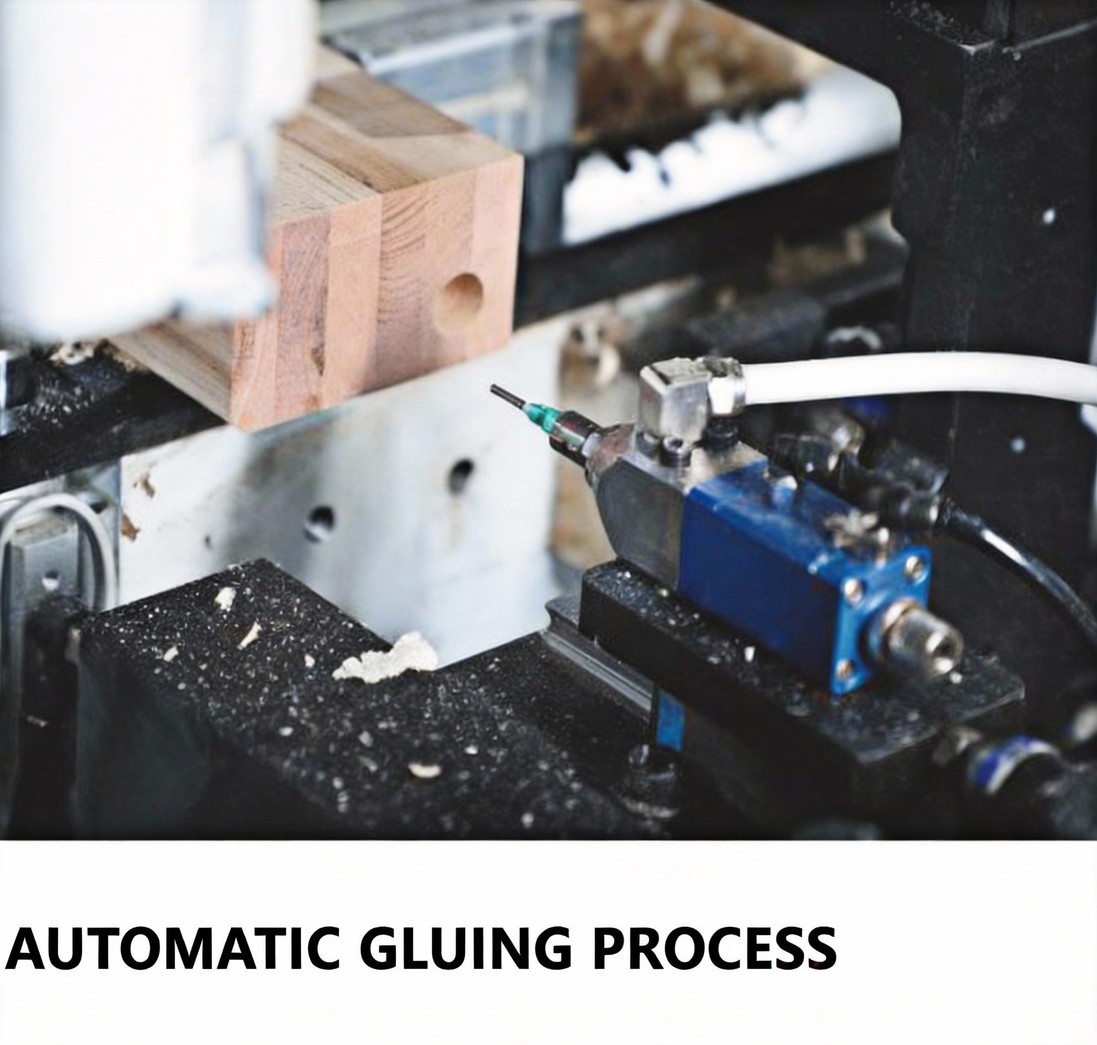

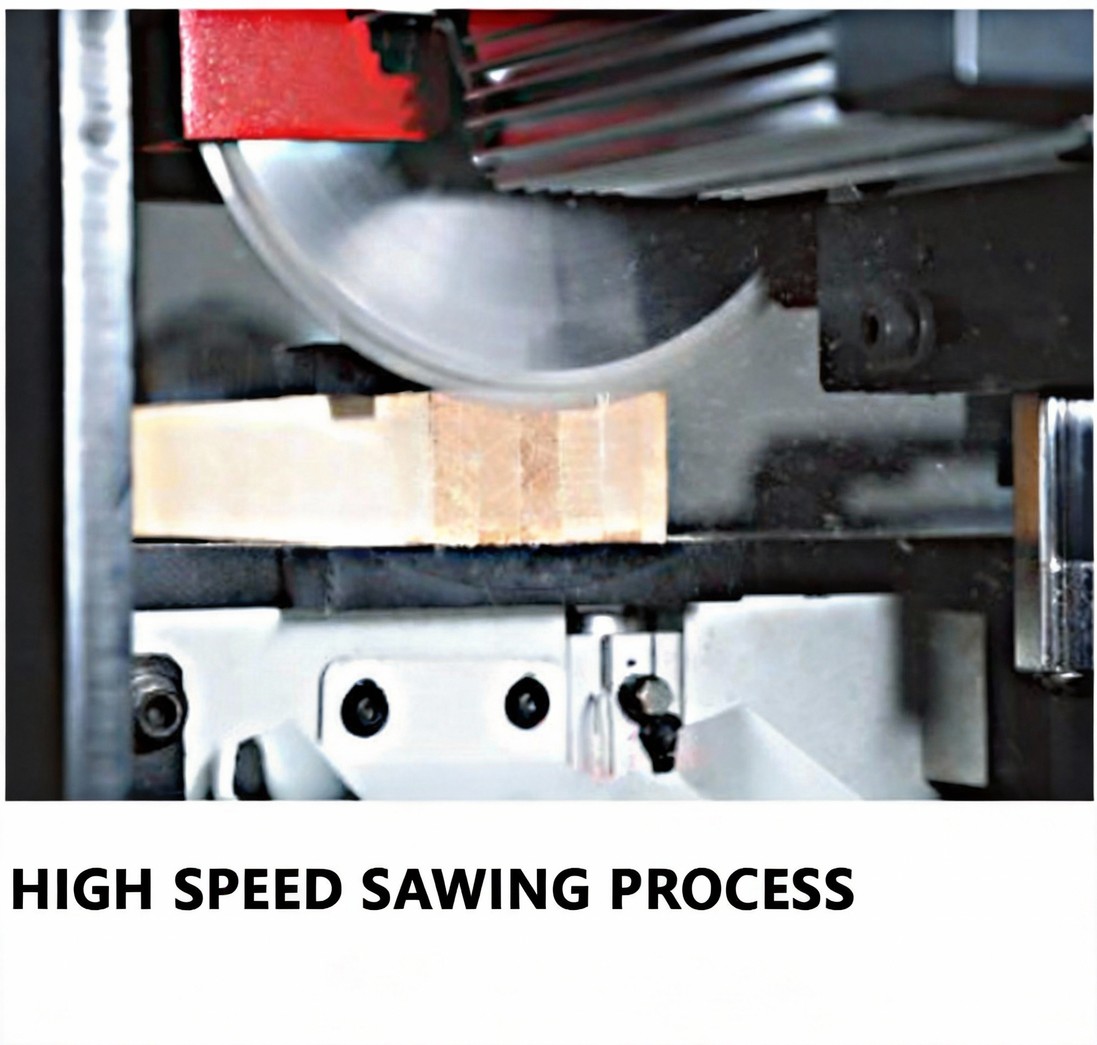

1.Simultaneous left-right cycle processing, integrating precision cutting, drilling, multi-sided profiling, gluing, dowel insertion, back drilling, and automatic unloading. Achieves 2–4 workpieces per minute.

2.Machine frame is welded from 10mm thick steel plates and square tubes, ensuring long-term stability and no deformation. Annealed and precision machined by CNC gantry milling for high accuracy and stable operation.

3.Equipped with heavy-duty precision linear guideways for stable performance, meeting the high strength and accuracy requirements of premium workpiece profiling.

4.Electrical components from Schneider (France). Inverter from renowned brand KBDE, enabling high-performance precision positioning and stable low-speed operation.

2.Machine frame is welded from 10mm thick steel plates and square tubes, ensuring long-term stability and no deformation. Annealed and precision machined by CNC gantry milling for high accuracy and stable operation.

3.Equipped with heavy-duty precision linear guideways for stable performance, meeting the high strength and accuracy requirements of premium workpiece profiling.

4.Electrical components from Schneider (France). Inverter from renowned brand KBDE, enabling high-performance precision positioning and stable low-speed operation.

Parameter | ST-1212 |

Processing Range | X-axis travel 1200mm, Y-axis travel 120mm |

Maximum Operating Speed | 50m/min |

Maximum Machining Speed | 15m/min |

Total Equipment Power | 40kW |

Table Structure | Double-End Moving Table |

CNC System | LNC (Taiwan) CNC System + PC Control |

Servo Drive | Delta Bus Servo, supporting EtherCAT / CANopen communication |

Drive Method | X-axis precision rack (high-speed, low-noise), Y-axis precision ball screw (high-accuracy, low-noise) |

Machine Frame | Heavy-duty steel structure welded, annealed at 600°C for stress relief |

Transmission Configuration | Precision Heavy-Duty Guideways |

Next

End

.png)